Basic HSE information about Working in explosive environments and set of tools to be used at work

Working in explosive environments

- Workplace Information

- Toolbox Information

- Check Your Knowledge

- Action Focus Campaign

IMPORTANT INFORMATION

- Use only certified and approved tools.

- Make sure there is no ignition source in a hazardous area.

- Do not ignore leaks but report them immediately to your manager.

- Do not perform hot work within 2 hours after a hazardous liquid is delivered.

- Clean up spills immediately.

WHAT IS IT?

Around the world, there are several directives for working in explosive environments and situations where there is a risk of gas and dust explosion. The purpose of the directives is that employers must ensure the safety and health of workers in areas with explosion hazards. This involves the control of conditions in an explosive atmosphere, in situations where it is not possible to eliminate the explosion hazard by substitution of substances. Strict requirements are therefore imposed on the workplace, on work equipment and on materials.

In Europe they use the ATEX 153 directives. ATEX is the abbreviation for the French words ATmosphères EXplosibles. In the USA this is governed by the National Electrical Code (NEC), in Canada by the Canadian Electrical Code (CEC).

Globally, the standards are set by the International Electrotechnic Commission (IEC). The standards on explosion safety are the IECEx standards and deal with the certification of products and personal competences. The purpose of IECEx is to harmonize national and international Ex standards.

In addition to the directives to protect people who work in explosive environments, there are also directives for manufacturers that deal with standards equipment and products must meet.

Employer measures:

- classify work environment into zones (areas with risk of explosions)

- identify what explosive substances are and in what quantities they are present

- what ignition sources exist and what their risks are in the work environment

- assess explosion risks and take precautionary measures

- a plant responsible employee must properly construct, inspect and maintain plants within the hazardous area

- train and certify employees

Only suitably trained persons should work in explosive environments.

What will you learn during a training course?

- what the risks are from and in the workplace

- when and where explosions may occur

- what ignition sources you may have to deal with

- what hazard zones a facility is classified in and what that zoning means

- which devices may be installed or used in which zone and which may not

- how those devices are marked and what exactly those markings mean

- the most important thing: how to prevent explosions

HAZARDS

There are three basic factors that can cause an explosion. This is called the fire triangle:

- flammable gas, vapor, mist or dust

- oxygen or air

- ignition source (electrical or a non-electrical ignition source)

Static electricity

Consider static electricity as an ignition source. Answer questions such as:

- how does static electricity arise?

- and where on can static electricity arise and pose a risk?

PREVENTION

- remove one of the three factors from the fire triangle

- removing the ignition source is most practical (also consider static electricity as an ignition source)

- replace a combustible substance with a substance with no or less combustible properties

- keep a flammable substance within a process and do not allow it to mix with the plant environment

- work with ventilation: the concentration of the lower explosion limit cannot be reached

- work under low-oxygen conditions

- remove ignition sources in places where there may be a risk of explosion

- ignition sources must meet an appropriate level of protection so that the probability of ignition is sufficiently reduced

- clean up spills immediately

- use only certified and approved tools

- do not perform hot work within 2 hours of delivering a hazardous liquid

- do not ignore leaks but report them immediately to your manager

Explosion hazard areas must be clearly marked with a warning triangle.

PROTECTION

- alerts indicate the potential for danger

- understanding of zoning of the work environment (areas at risk of explosions)

- permit to work: what personal protective equipment and tools are required

- task risk analysis: what additional personal protective equipment, if any, is needed

- training: what are the principles and operation of different protection methods for electrical and mechanical equipment

- understanding the origins of explosion hazards and recognizing hazardous situations

- make a last minute risk analysis before you start to work

No accurate information about personal protective equipment? Ask your manager about it.

IN THE CASE OF...

If you suspect that there may be a risk of explosion, for example due to static electricity, call in an expert. He or she will give advice on measures to limit the generation of static electricity or how to dispose of a static charge safely.

Any incident that occurs can have serious consequences for people, facilities and the environment. Make sure you are familiar with the proper procedure in case incidents occur.

Start your daily work with safety!

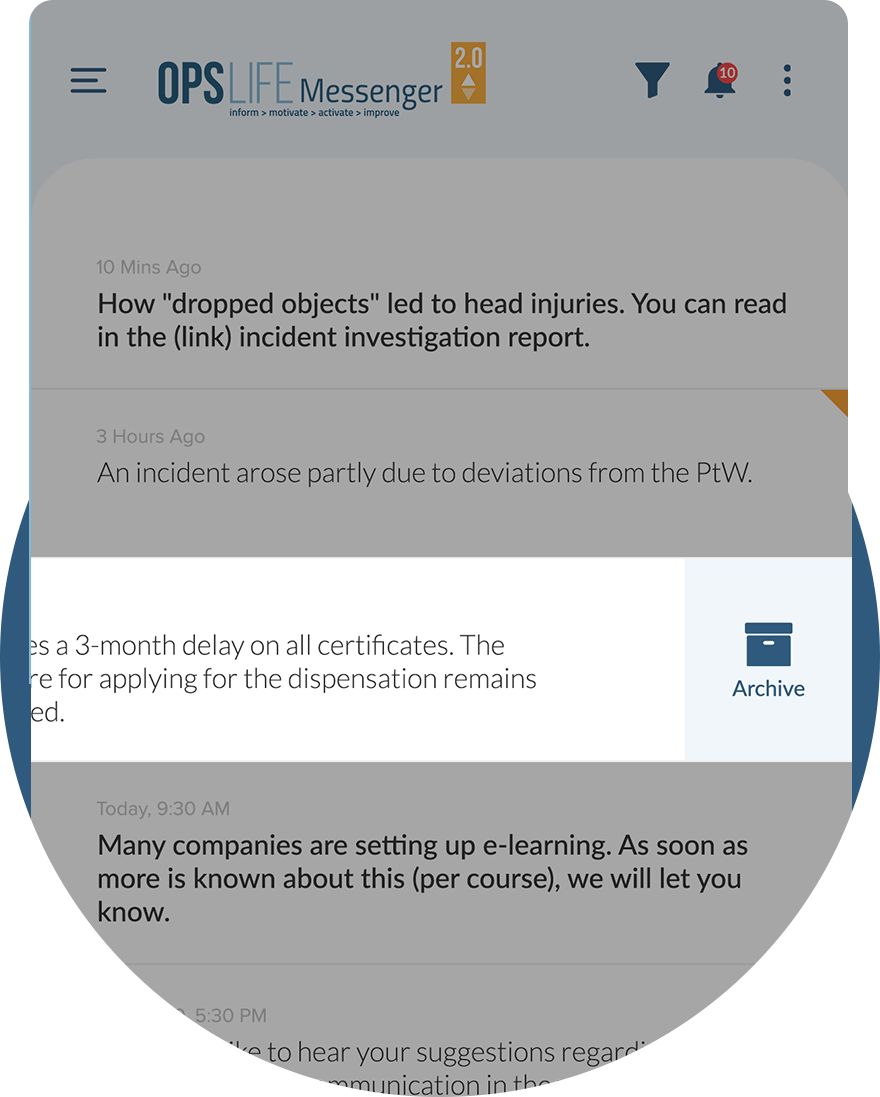

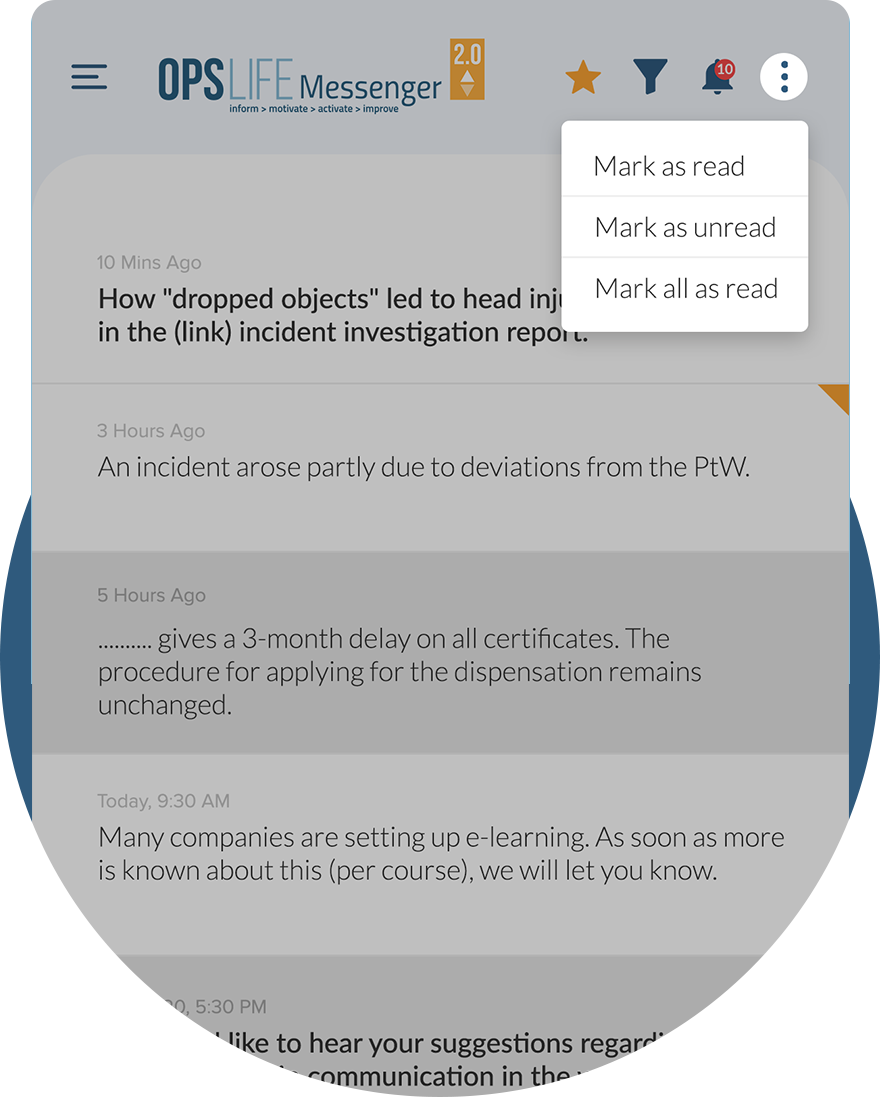

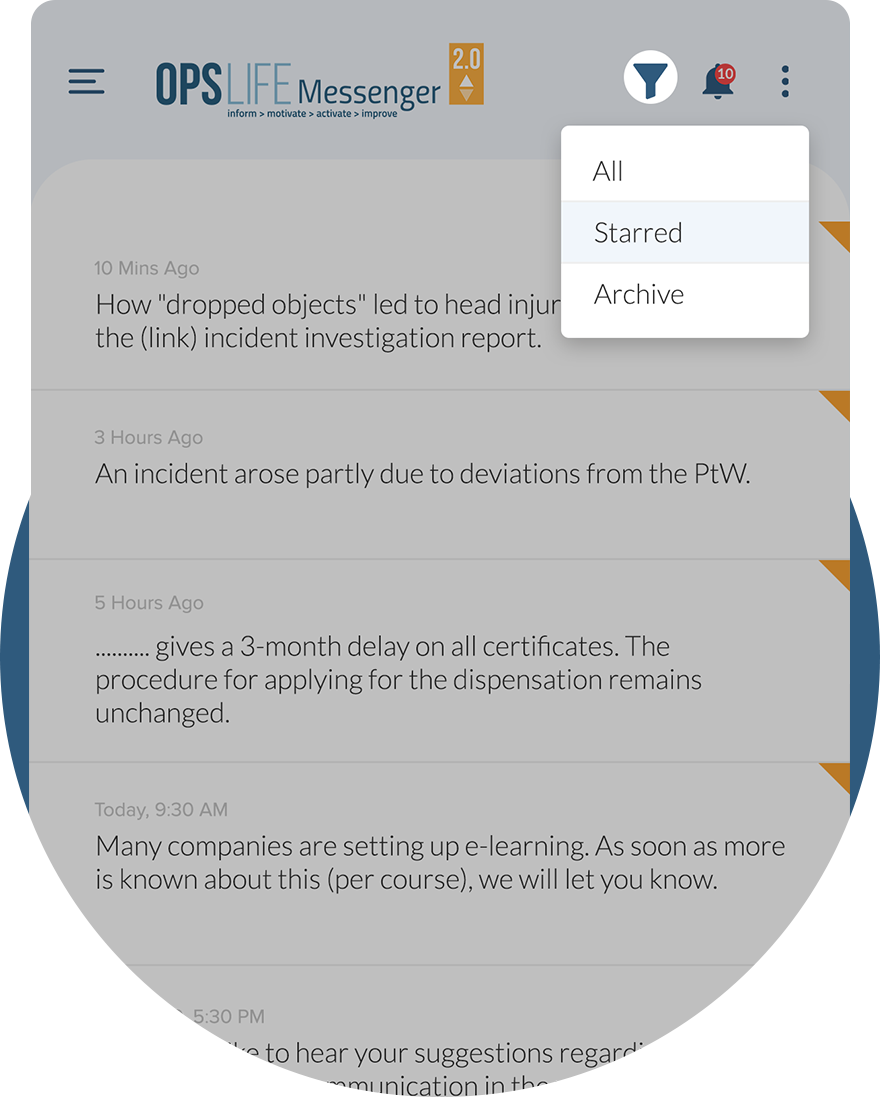

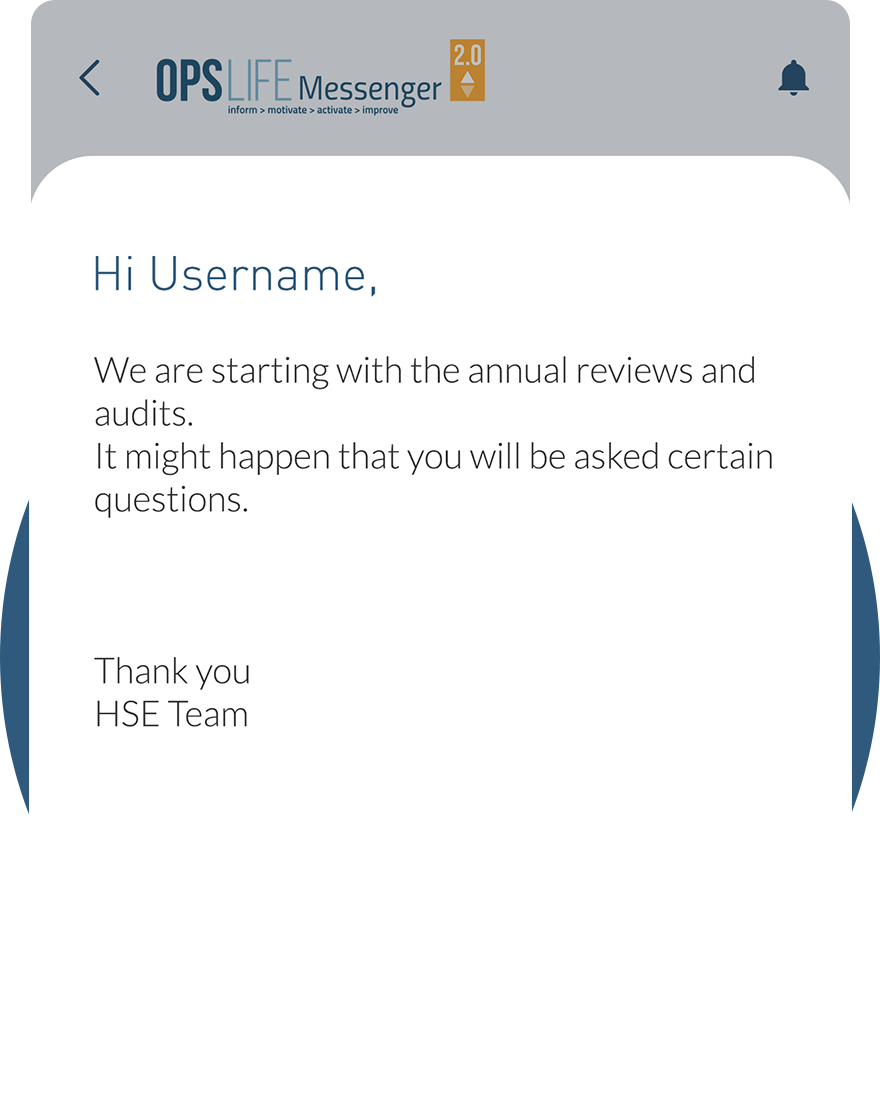

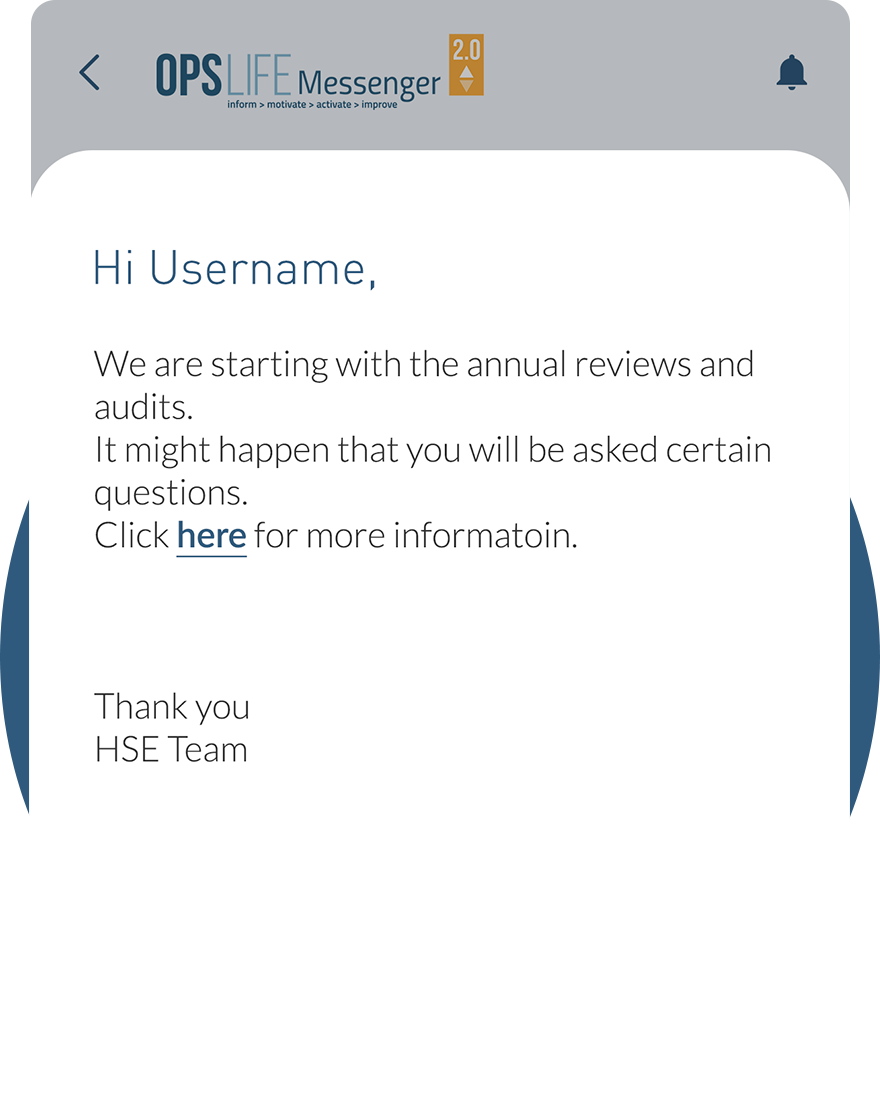

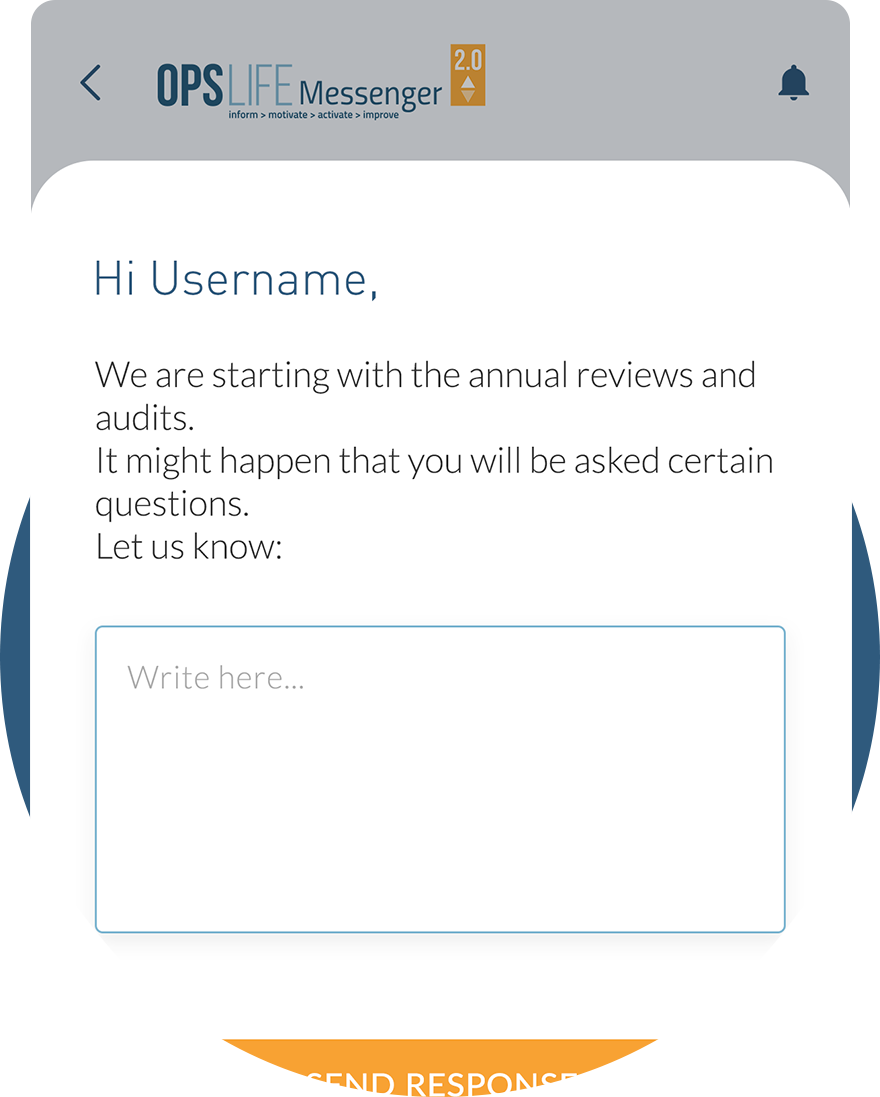

Onscreen presentation is very useful to use during work preparation or toolbox meetings. It provides short and concrete information. Five questions and answers at the end of presentation can be used to make the meeting more interactive and to give conversation a boost.

Be always prepared for the work!

It is of utmost importance to be well prepared before you start the work.

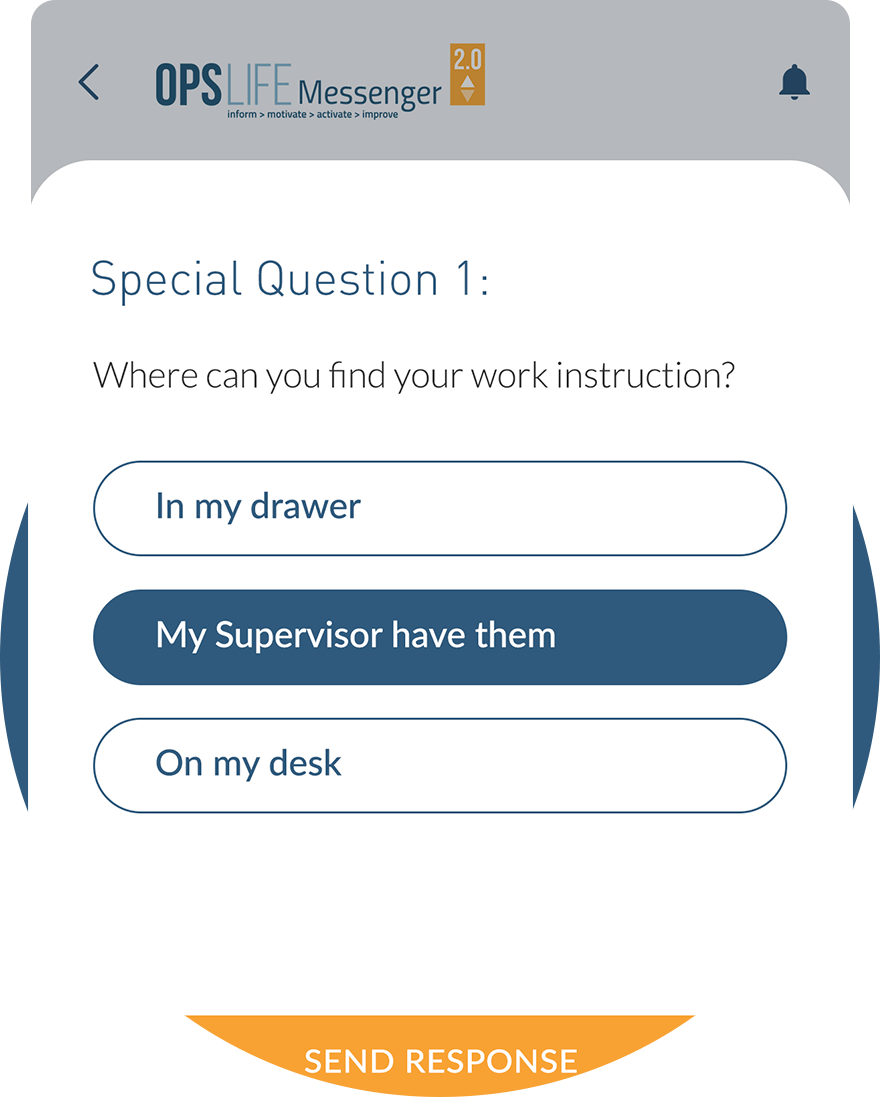

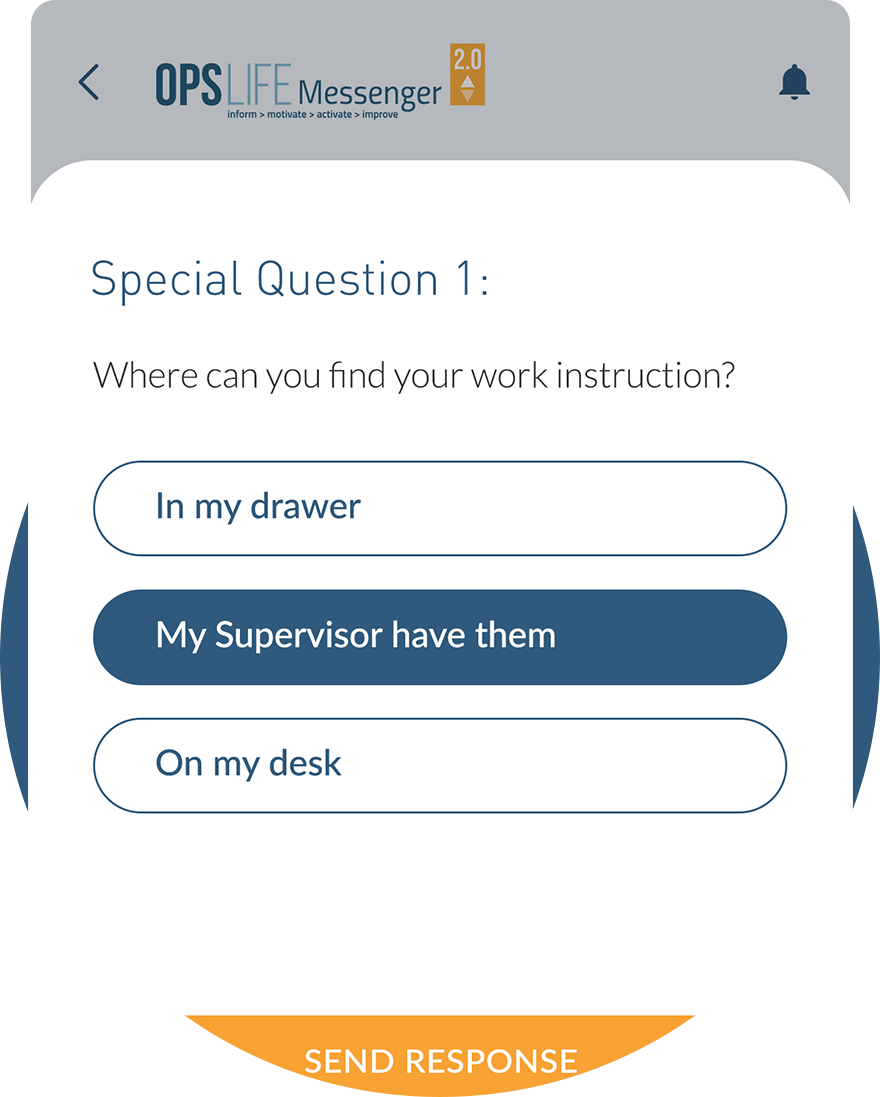

By clicking on the button below you can check your knowledge about this HSEQ subject.

After completion of the knowledge check, your certificate will be visible in

MY ACCOUNT > My training.