Basic HSE information about Travelling by vessel and set of tools to be used at work.

TRAVELLING TO AND FROM A PLANT AT SEA BY VESSEL

- Workplace Information

- Toolbox Information

- Check Your Knowledge

- Action Focus Campaign

IMPORTANT INFORMATION

- Once on board a vessel you should wear a lifejacket.

- All participants involved in the transfer should be briefed prior to the transfer.

- Communications should be maintained during operations.

- All equipment should be inspected and maintained.

- You must have followed a course to be prepared for the conditions and hazards at sea.

WHAT IS IT?

It is estimated that every year around seven million passenger transfers to and from a plant at sea by vessel are conducted. Personnel being transferred should be briefed prior to the transfer and should be familiar with the method of tranfer and the equipment being used. Personnel involved in a transfer should be physically able to make the transfer and should understand the intended activity. Passengers are usually transferred in a carrier (i.e. a net, basket or capsule) which is lifted by crane onto the plant at sea.

Crew supply encompasses a range of different methodologies including crane transfer, walk to work, step-over (to a ladder or boat landing) and swing rope. Of these, crane transfer is the most common method.

HAZARDS

- risks in port while boarding/unloading the vessel, such as falling from the gangway to shore

- risks of major accidents that arise from the interaction between the vessel and the installation, such as collision or ignition of hydrocarbon leaks

- fall from a height, i.e. fall on hard surfaces and fall into water

- drowning

- impact or crushing injuries

- impact with either the Transfer Boat or receiving vessel after a slip or fall

- sprains, twists and/or pulls

- cold water immersion

- hazardous weather and/or sea conditions

- other conditions inherent to the specific locality (e.g. lack of visibility during foggy hours)

Crane transfer

The highest number of incidents occur during pick-up of the carrier, as opposed to landing. This is typically due to misalignment between the crane hook and the carrier during pick up (known as an off-centred lift), causing the carrier to swing in an uncontrolled manner. When using collapsible baskets the challenges are increased, as the crane operator needs to maintain tension in the net during heave cycles.

Sea-state

Wave height, direction, and current will affect vessel motions and be the main influencing factor for vessel station-keeping. In addition to heave, the horizontal motions (surge, sway and yaw) will be significant factors for pick up and landing phases on the vessel deck. For vessel to vessel transfers, pitch and roll will have an impact on crane tip motions and control of the load.

Wind

Wind may impact the crane operator’s ability to control the load. The limits specified for the crane and the transfer carrier both need to be considered .

Light and visibility

Transfers at night and in poor weather conditions may impact the safety of the transfer. The risks of reliance on non-visual communications should be assessed.

Temperature

Low temperatures present additional risks to passengers such as reducing the passengers’ ability to grip, which is especially important in standing carriers. You should consider the risk of hypothermia, equipment limitations and performance and emergency recovery procedures.

PREVENTION

You must have followed a course to be prepared for the conditions and hazards at sea in order to travel to and from a plant at sea. Familiarisation training should be provided to all personnel involved in crane transfer operations. This should cover pre-transfer inspection of the crane and carrier, passenger briefings, crew briefings, operational best practice and emergency operations.

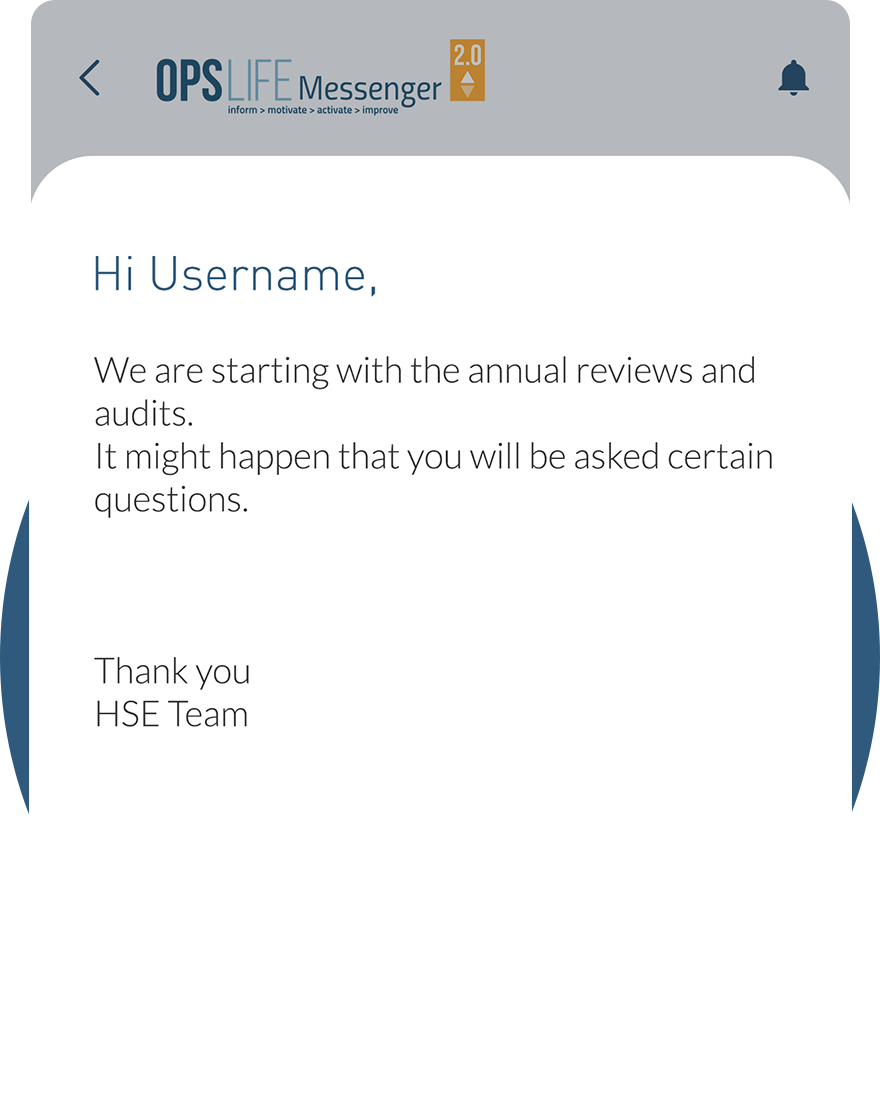

All participants involved in the transfer should be briefed prior to the transfer to ensure that the safety and emergency procedures to be followed are understood

The person(s) responsible for a safe transfer should maintain and store safety equipment. All safety equipment should be easy to find and access. They must be:in good condition and meet appropriate standards or specifications. This means that they should be maintained or serviced according to the manufacturer’s specifications. There should be a first-aid kit and a fire extinguisher inside of the vessel. There must always be 2 means of communication.For example, a radio and a mobile phone in a waterproof cover.

Communications should be maintained during operations and should be tested and verified at regular intervals throughout the transfer operation.

A risk assessment should be conducted prior to the transfer.

PROTECTION

Personal protective equipment should be worn. The minimum personal safety equipment you must carry depends on the type of vessel you’re in.

Once on board you should at least wear a lifejacket. Apart from wearing a lifejacket it’s recommended to carry:

- a kill switch lanyard

- a waterproof and working torch

- a wetsuit

- a helmet

- visual signaling devices

- sound signaling devices

- a Personal locator beacon

Ask your company about this.

All equipment used for personnel transfer operations should be inspected and maintained. Personnel transfer equipment may be classified as lifting equipment, safety/lifesaving equipment, or both.

The vessel must provide a stable and safe landing platform in all anticipated conditions of operation. Vessels should be assessed for their suitability including:

- motion characteristics and station-keeping

- view and communications from bridge

- landing area

IN CASE OF...

Any incident that occurs during work can have a severe impact on people, installations and the environment. Ensure that you are familiar with the right procedure in case incidents occur. If not, ask your company for details.

Start your daily work with safety!

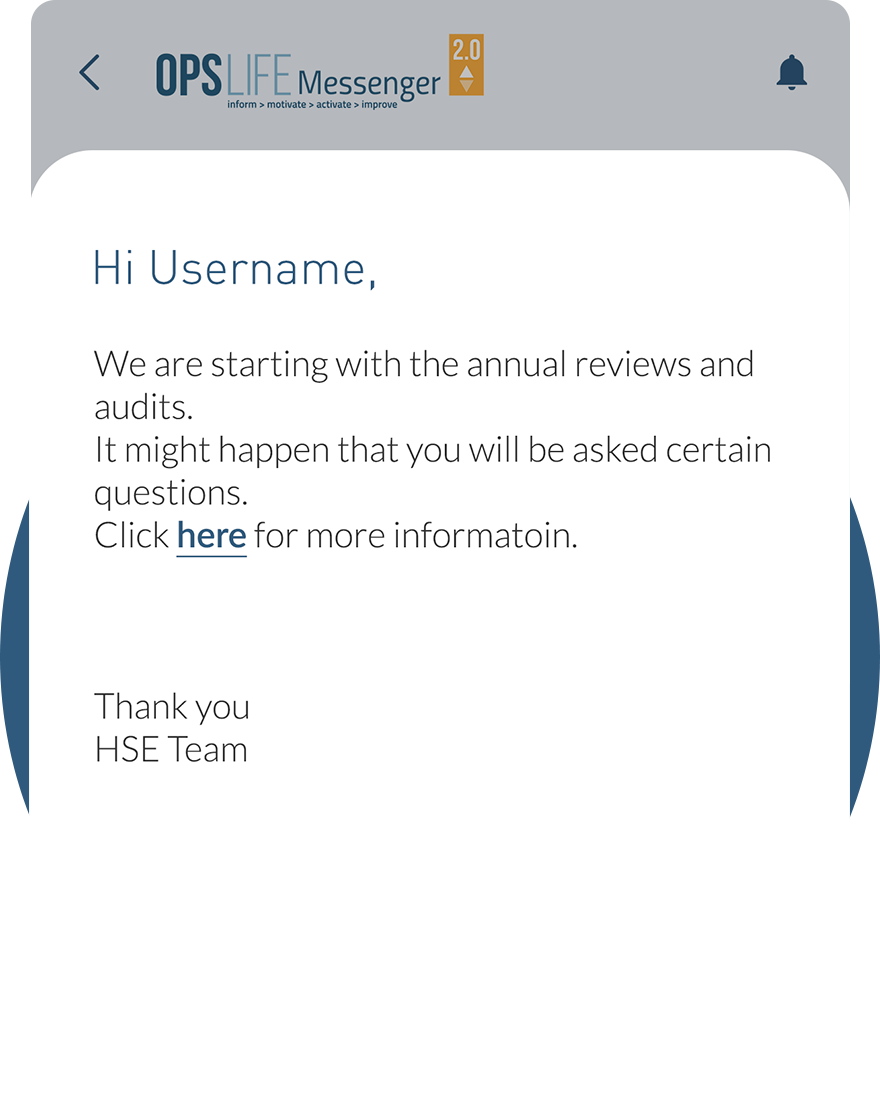

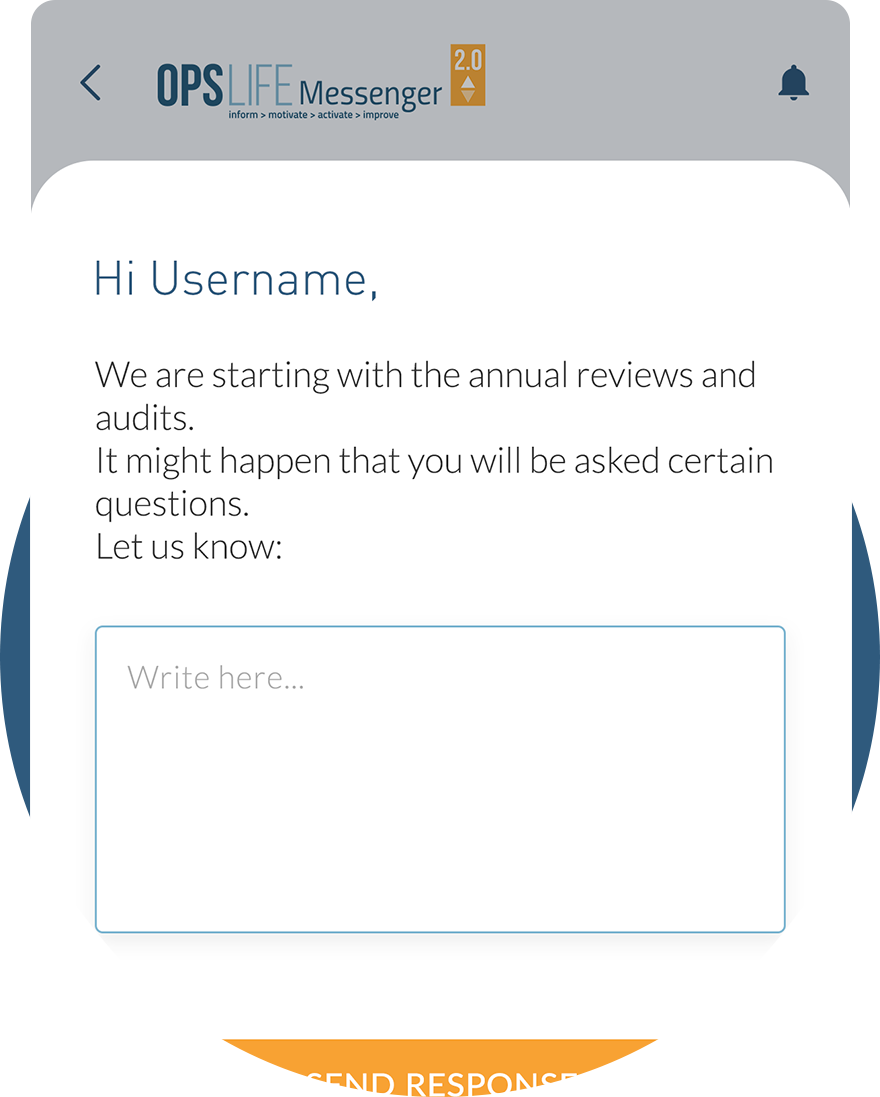

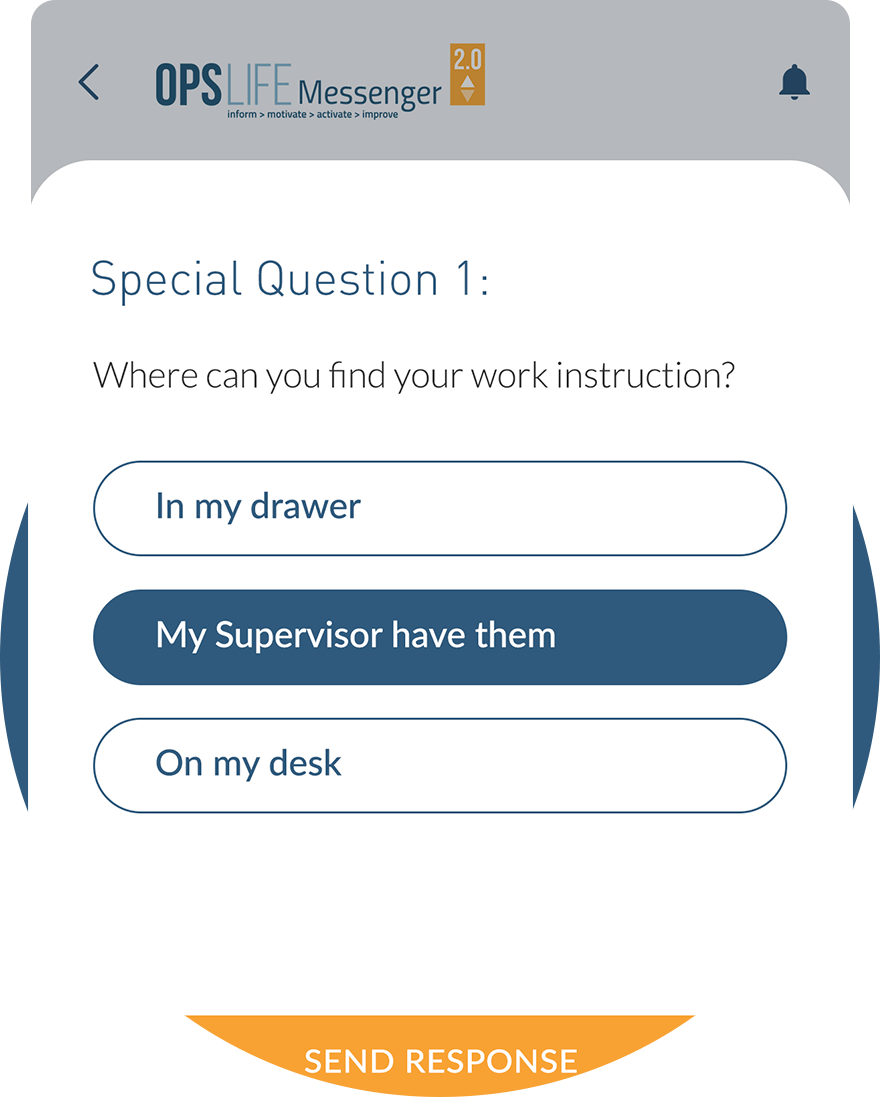

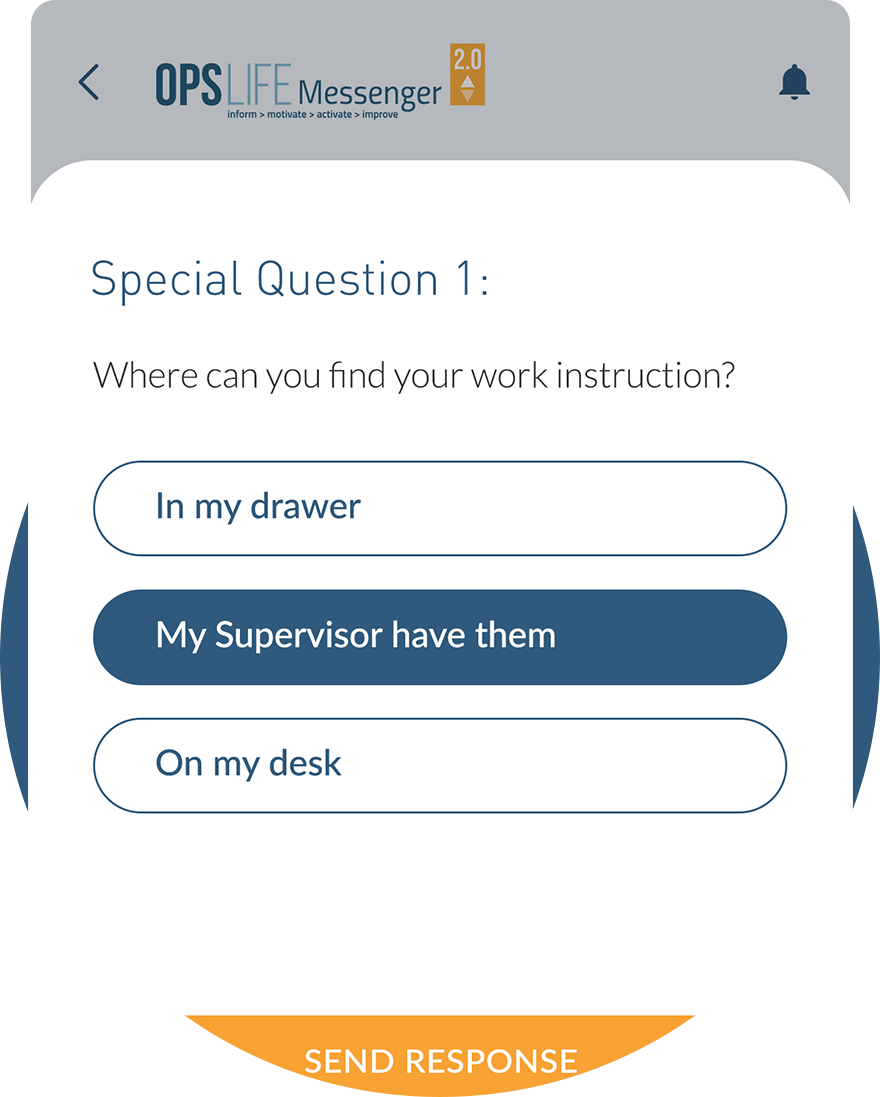

Onscreen presentation is very useful to use during work preparation or toolbox meetings. It provides short and concrete information. Five questions and answers at the end of presentation can be used to make the meeting more interactive and to give conversation a boost.

Be always prepared for the work!

It is of utmost importance to be well prepared before you start the work.

By clicking on the button below you can check your knowledge about this HSEQ subject.

After completion of the knowledge check, your certificate will be visible in

MY ACCOUNT > My training.