Basic HSE information about Process safety - Safeguarding and set of tools to be used at work.

Process safety - Safeguarding

- Workplace Information

- Toolbox Information

- Check Your Knowledge

- Action Focus Campaign

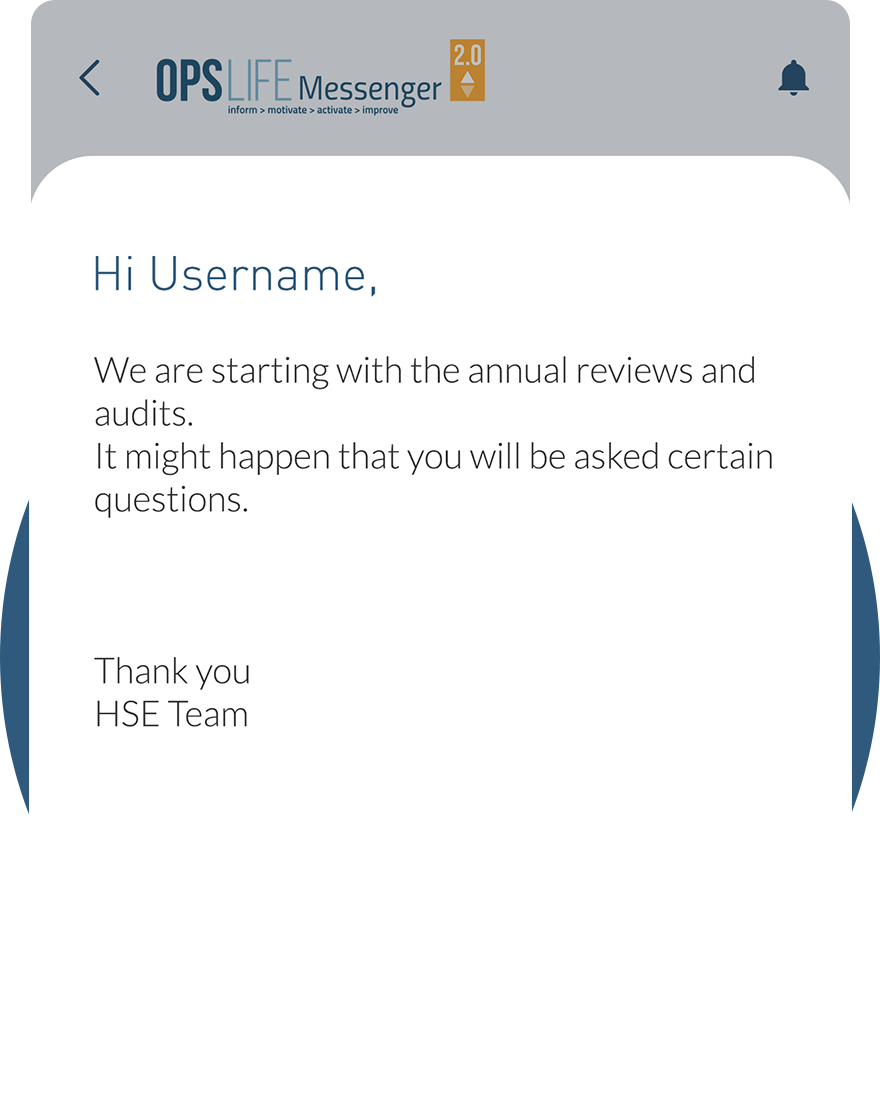

IMPORTANT INFORMATION

- Follow the correct safety precautions and check them regularly.

- Discuss the risks of the job and relevant safety precautions beforehand with all involved.

- Ensure that measurements are conducted regularly to identify any (potential) hazards and hazardous conditions.

- Satisfy yourself that all systems and parts are safe.

- Stop work immediately if anything unexpected occurs happens.

WHAT IS IT?

Process safety is primarily concerned with the identification of potential hazards and hazardous conditions associated with process systems; the methods of predicting the possible severity of these hazards; and control or mitigation strategies. Most process systems are protected by layers of safeguards, which form an integral part of workplace safety. The aim is to manage safety risks that could otherwise lead to incidents.

HAZARDS

Process hazards include fire, explosion, and toxic release. These hazards are associated with incidents which occur at low frequencies, but can have catastrophic consequences.

PREVENTION

BEFORE YOU START WORKING

- hold a pre-job meeting and discuss potential hazards

- inspect your workplace

- ask your company about what to do in case of an emergency

- together with an expert, check that the system (components) you are going to be working on is safe

- ensure that control measures have been conducted

DURING THE JOB

- regularly check that the system you are working on is still safe

- ensure that you are physically shielded from any potential hazard

- when necessary, take additional precautions – ask your company for more information about this

NB. An Operator from the Operations Department will perform physical safeguarding in accordance with a safety plan; they undertake the depressurizing and cleaning of an installation

PROTECTION

Always use the correct Personal Protection Equipment (PPE). Extra protection equipment may be required for work that entails a specific risk. Ask your company about this. The Permit to Work also states which basic and additional PPE you must wear.

HOW TO SAFEGUARD THE PROCESS

- by (physically) separating and/or blocking system components; there are differing methods that can be employed to achieve this. Ask your company for further information in relation to this

- ask your company about the regulations, their safety plan, reporting and registration requirements

- ensure that measurements are carried out regularly to identify any (potential) hazards and hazardous conditions

IN CASE OF...

Avoiding or removing safeguarding in the workplace can lead to disastrous consequences. In case of an incident: STOP ALL WORK, RAISE THE ALARM and ASSIST any affected person. Always take care of your own personal safety!

PLEASE NOTE…

- stop work immediately if you are unclear about anything, when there is danger, or if there are deviations from working plans

- block subsequent work if you have not completed your work

- never improvise

- immediately report any defects, damage etc. with the system (components)

Start your daily work with safety!

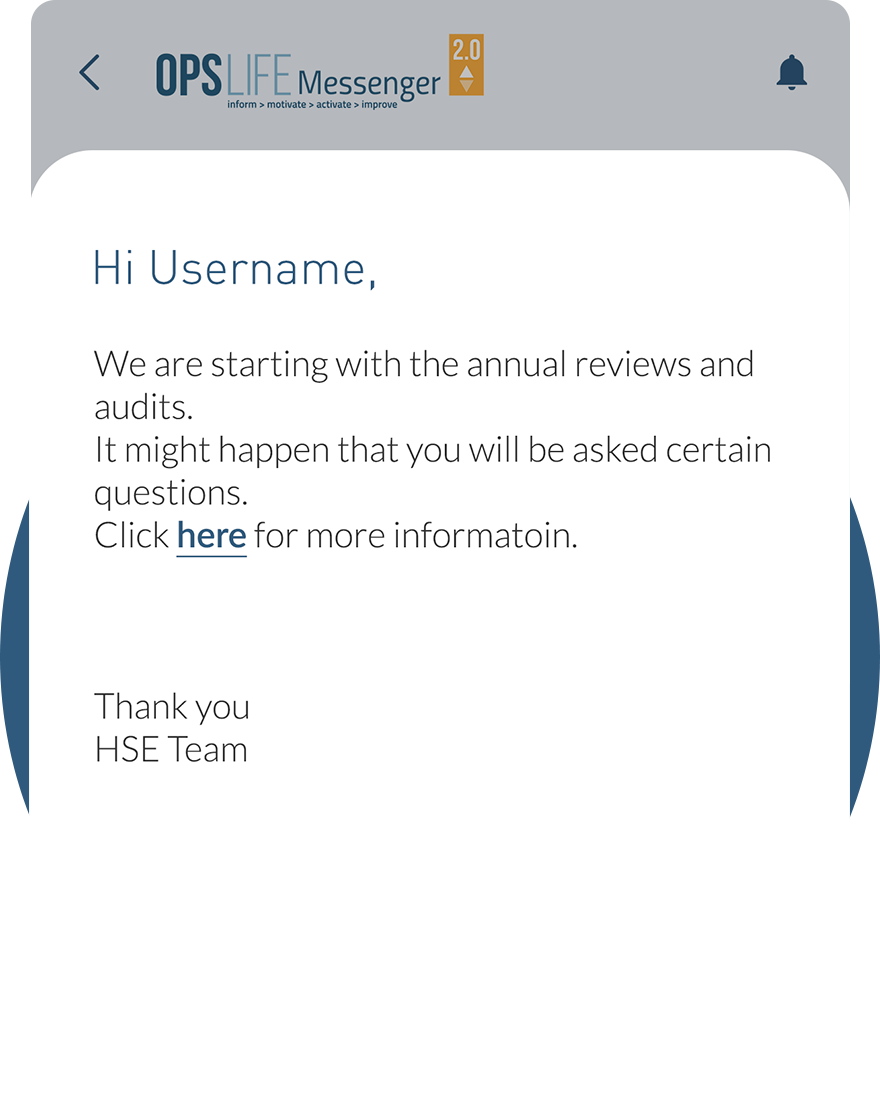

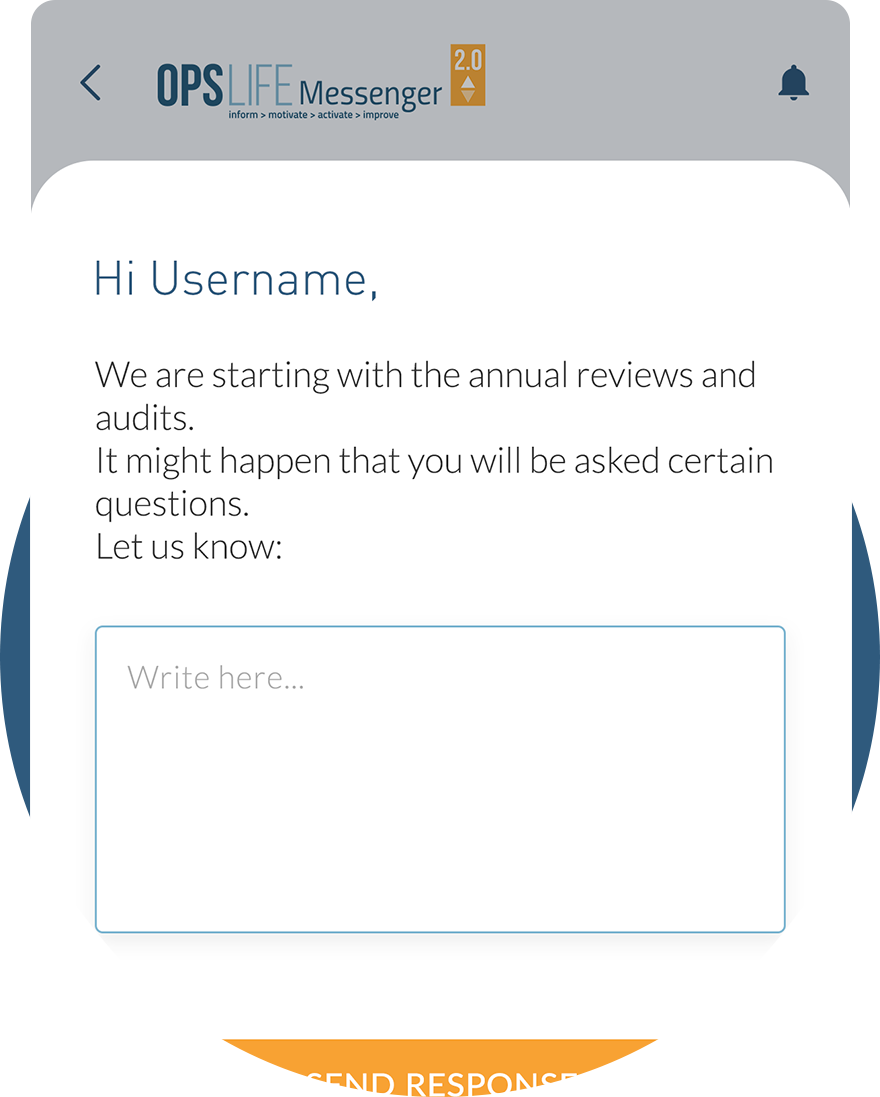

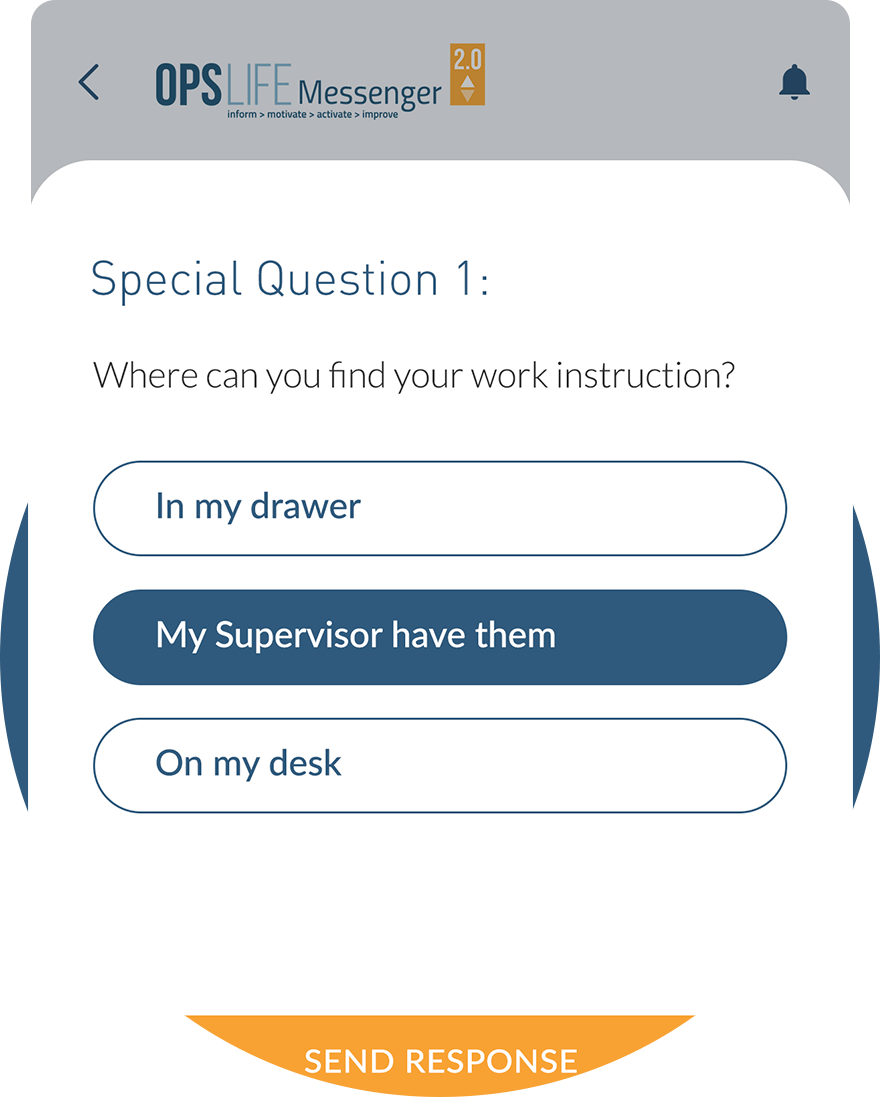

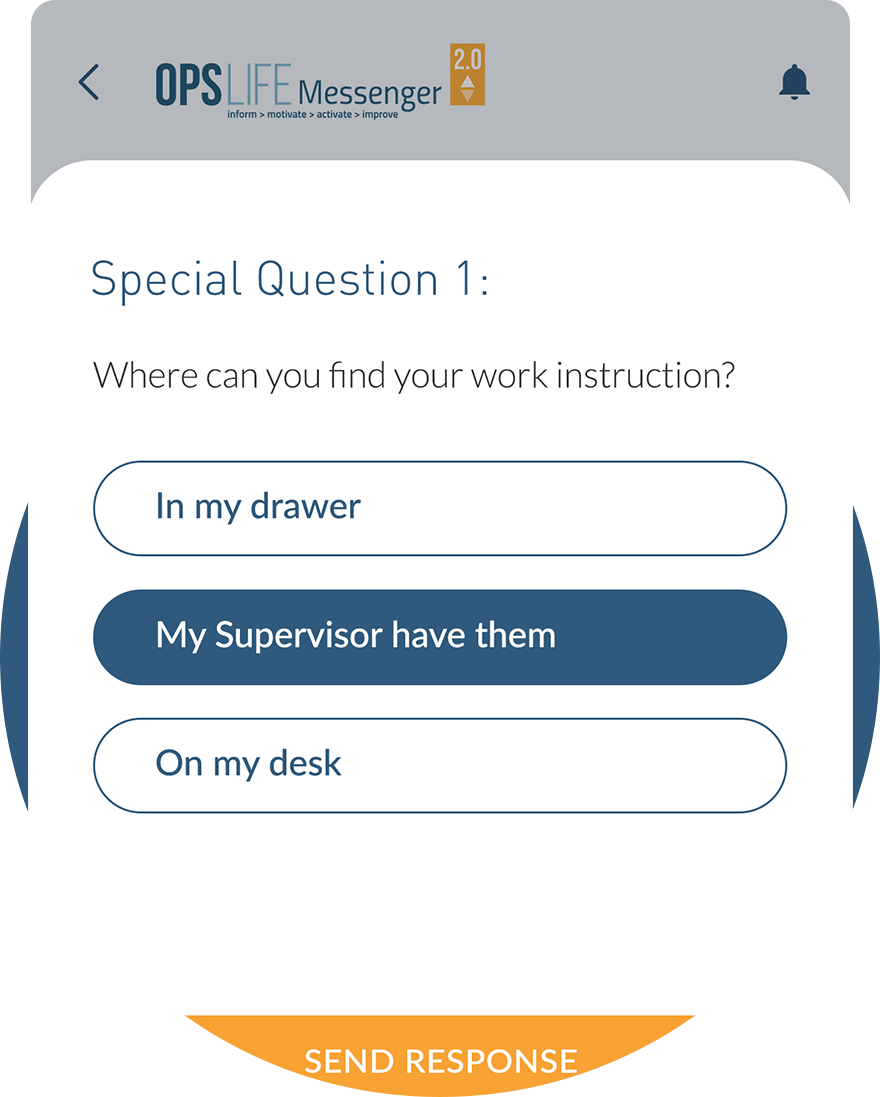

Onscreen presentation is very useful to use during work preparation or toolbox meetings. It provides short and concrete information. Five questions and answers at the end of presentation can be used to make the meeting more interactive and to give conversation a boost.

Be always prepared for the work!

It is of utmost importance to be well prepared before you start the work.

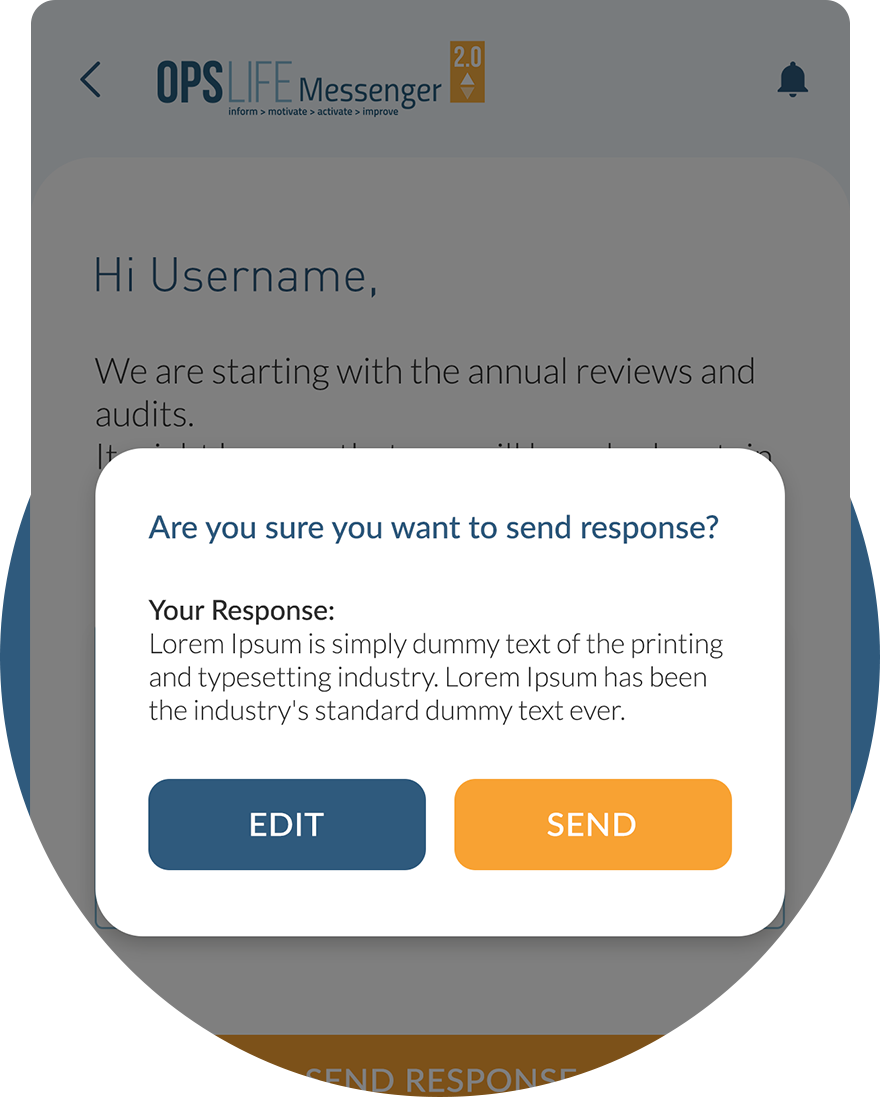

By clicking on the button below you can check your knowledge about this HSEQ subject.

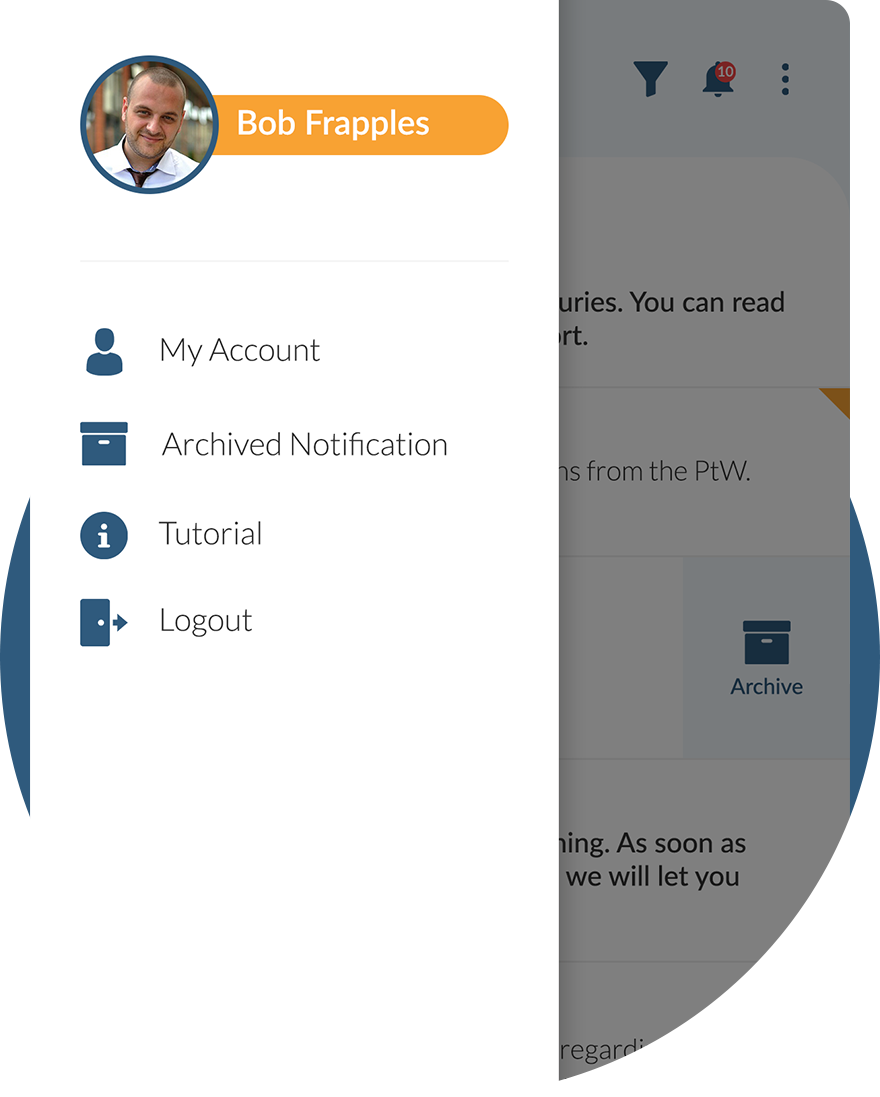

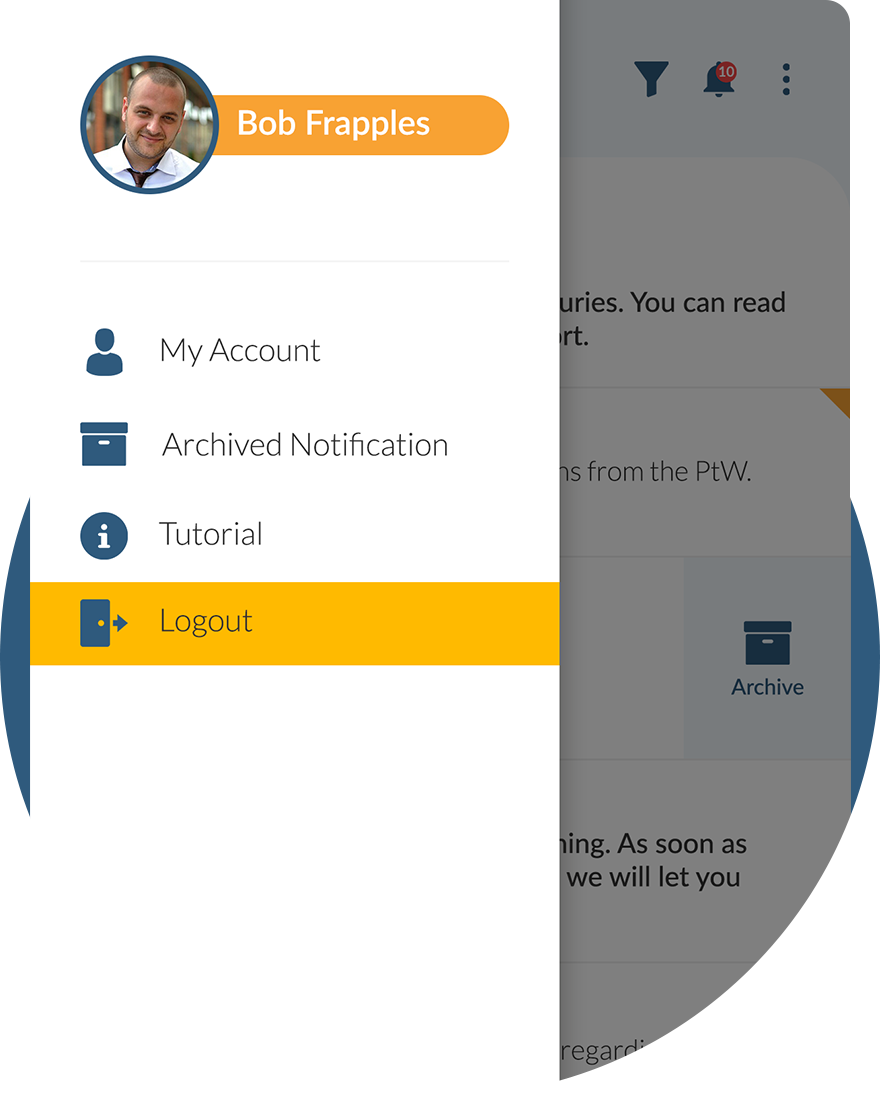

After completion of the knowledge check, your certificate will be visible in

MY ACCOUNT > My training.