Basic HSE information about Flange joints and set of tools to be used at work.

Flange joints

- Workplace Information

- Toolbox Information

- Check Your Knowledge

- Action Focus Campaign

IMPORTANT INFORMATION

- Make sure that gaskets, nuts and bolts are in good condition.

- Make sure that flanges are properly aligned.

- Always use the correct gaskets, nuts and bolts.

- Always use the correct flange-gasket combination.

- Make sure that bolted joints are tightened in the correct way.

WHAT IS IT?

A flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. Flanges are usually welded or screwed. Flange joints are made by bolting together two flanges with a gasket between them to provide a seal.

FLANGE ALIGNMENT

Flanges must be properly aligned to ensure that the pressure is distributed evenly across the entire gasket. Ask your company about their specific criteria.

HAZARDS

Potential hazards of faulty flange joints are numerous: from instant bodily injuries, damage to installations and pollution of the environment. Therefore ensure at all times that you are qualified to work on flanges, that you are using the proper PPE and the prescribed tools.

PREVENTION

One of the main potential sources of leaks are flange joints. Preventing leaks is very important because of possible implications for your safety and that of the environment. Only certified flange operators are permitted to perform work on flange joints. Ask your company about how to obtain certification.

BOLTS, NUTS AND GASKETS

Ask your company about their policies and procedures in relation to:

- how to keep bolts, nuts and gaskets in good condition

- flange alignment

- selecting the correct bolts, nuts and gaskets

- the correct flange-gasket combination

- the tightening sequence of bolted joints

PRESERVING FLANGE JOINTS

Ask your company about their policies and procedures in relation to preserving flange Joints.

FLANGE REGISTRATION AND LABELLING REQUIREMENTS

To verify the correct manner in which to work , all flange joints should be reported/registered. Furthermore, all joints should have a label physically attached on or to the relevant flange. Ask your company about their policies and procedures in relation to this.

PROTECTION

Use standard and additional Personal Protection Equipment (PPE), as stated in the Permit to Work.

IN CASE OF...

Any incident that occurs during working with flange joints can have a severe impact on people, installations and the environment. Make sure that you are familiar with the right procedure in case incidents occur. If not, ask your company.

Start your daily work with safety!

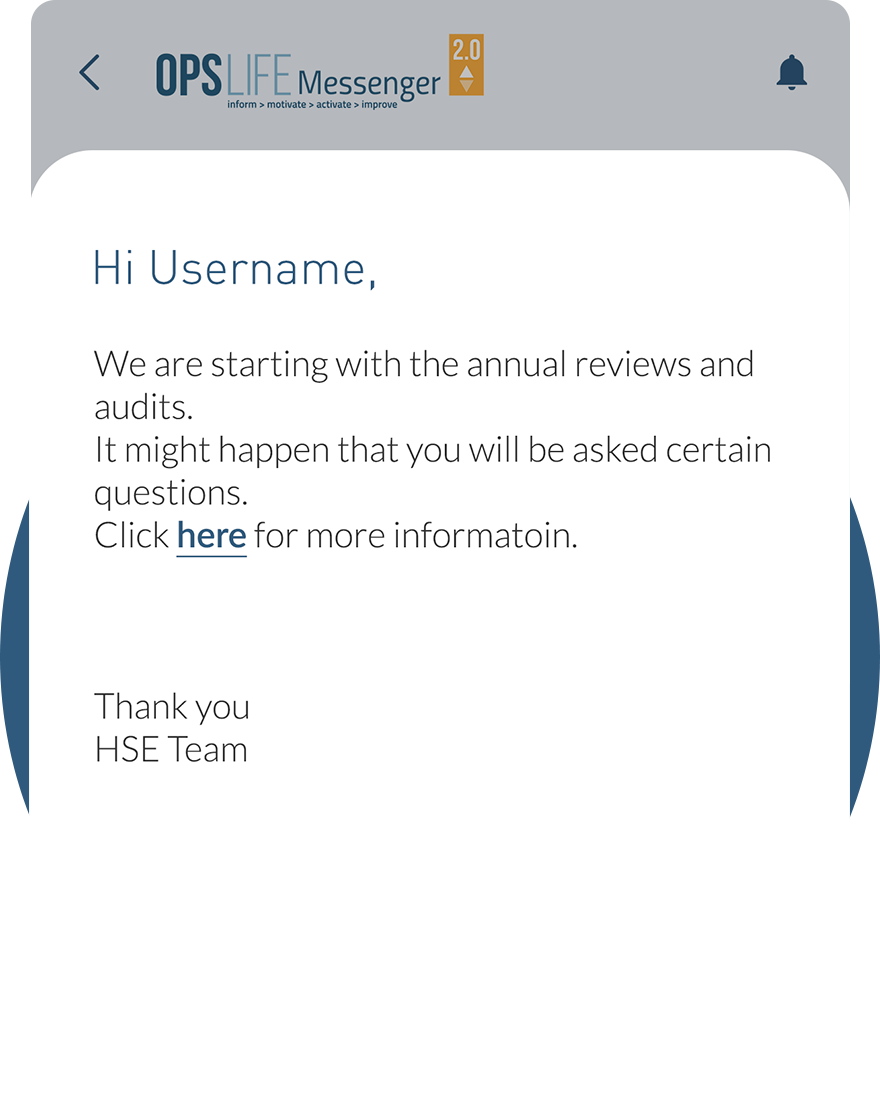

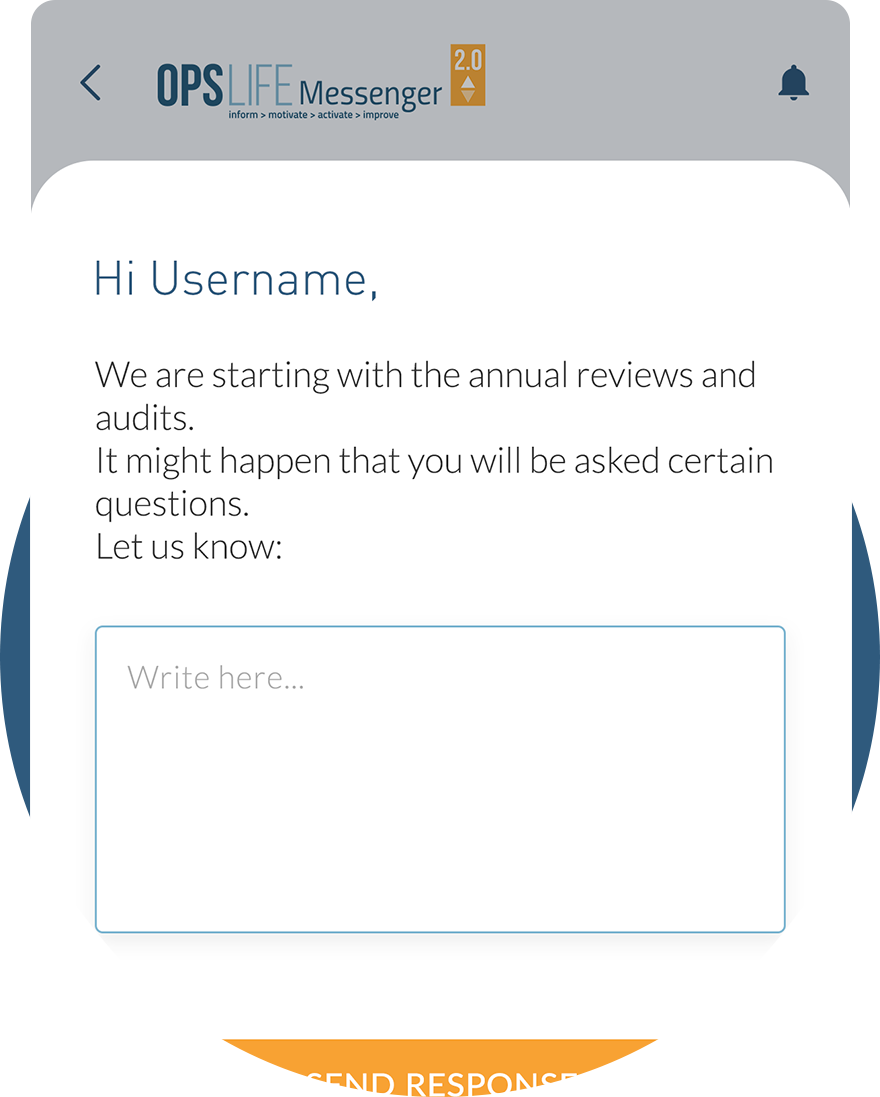

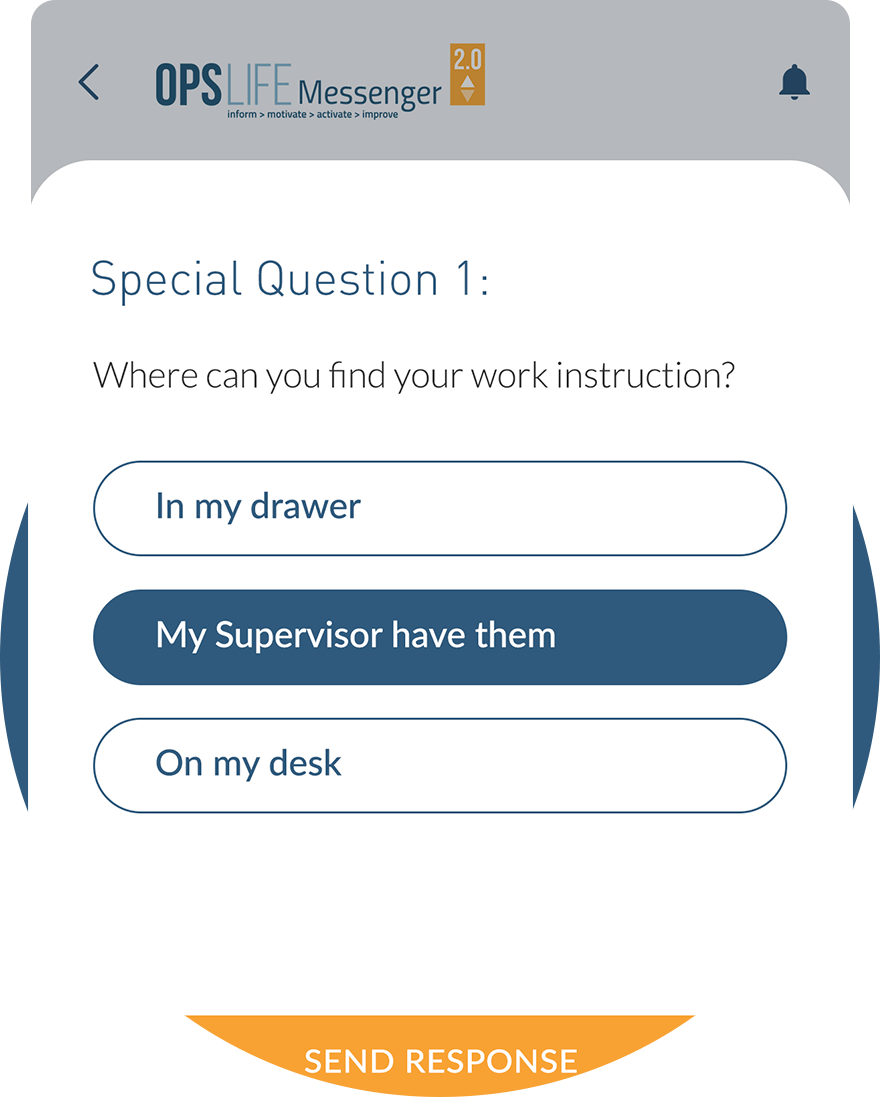

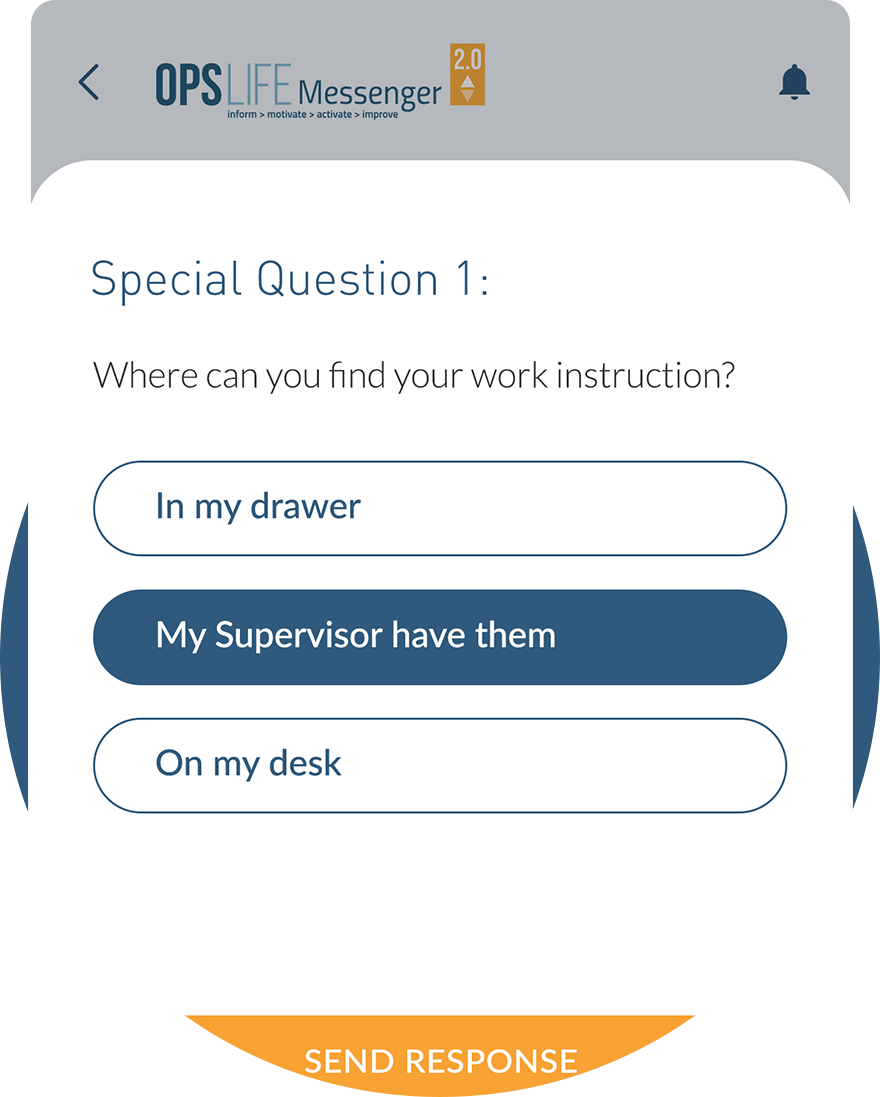

Onscreen presentation is very useful to use during work preparation or toolbox meetings. It provides short and concrete information. Five questions and answers at the end of presentation can be used to make the meeting more interactive and to give conversation a boost.

Be always prepared for the work!

It is of utmost importance to be well prepared before you start the work.

By clicking on the button below you can check your knowledge about this HSEQ subject.

After completion of the knowledge check, your certificate will be visible in

MY ACCOUNT > My training.